Thermocouple Wafer

TC Wafer is used in semiconductor manufacturing processes to provide real-time process monitoring and environmental temperature control at each stage of the process, such as etching, photolithography, CVD, PVD, testing, front-end and back-end packaging, etc. We provide highly customized products, through sophisticated technology and complete customer support services, so we can meet the various needs of users.

TC Wafer is used in semiconductor manufacturing processes to provide real-time process monitoring and environmental temperature control at each stage of the process, such as etching, photolithography, CVD, PVD, testing, front-end and back-end packaging, etc. We provide highly customized products, through sophisticated technology and complete customer support services, so we can meet the various needs of users.

|

☑ Temperature range:-100°C~1300°C

☑ High-level accuracy and reusability

☑ Strong thermal shock resistance

☑ Sturdy junction

☑ Certified calibration report

☑ Calibration service & maintenance consultation

|

|

✶ Application

- Measure the temperature stable time and temperature uniformity

- Calibrate the accuracy of temperature setting

- Assess the impact of load capacity

- Measure the temperature distribution of wafer

- Inspect the thermal stress from the center to the edge of the wafer

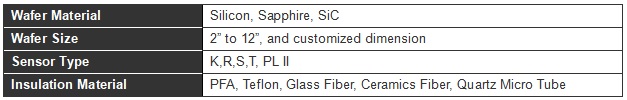

✶ Specification

✶ Operating Temperature

*we provide extra high accuracy wire

Temperature Monitoring System

If you need an integrated temperature monitoring system, we can provide you the solution.

Temperature monitoring system WaferBLE connects to the data collector TW-DC2301 through Bluetooth wireless communication to transmit real-time temperature data to the system. It can display and store records immediately, and provide various statistic data to assist the user in analyzing and statistics.

Temperature monitoring system WaferBLE connects to the data collector TW-DC2301 through Bluetooth wireless communication to transmit real-time temperature data to the system. It can display and store records immediately, and provide various statistic data to assist the user in analyzing and statistics.

I. High Accuracy Data Collector

| Data Collector TW-DC2301 can instantly transfer the data to the system, offering the ultimate in resolution (0.01 °C) and accuracy(0.01°C). Along with temperature it can also be used to measure resistance and voltage. |

|

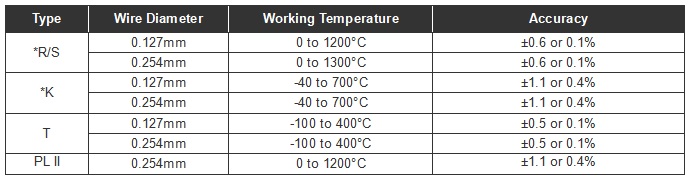

II. Temperature Monitoring and Analysis

WaferBLE can help you:

☑ Retrieve, report, analyze, and visualize data

☑ Embeddable results for real-time analytics and reporting

☑ Support data exploration and collaboration, enabling people of all skill levels to look rapidly at data from multiple perspectives

☑ Ideal tool for helping users improve the production efficiency of chip factories, and the yield rate of chip output

☑ With graphical analysis tools such as heat map and line chart, can help users easily understand the current status of process.

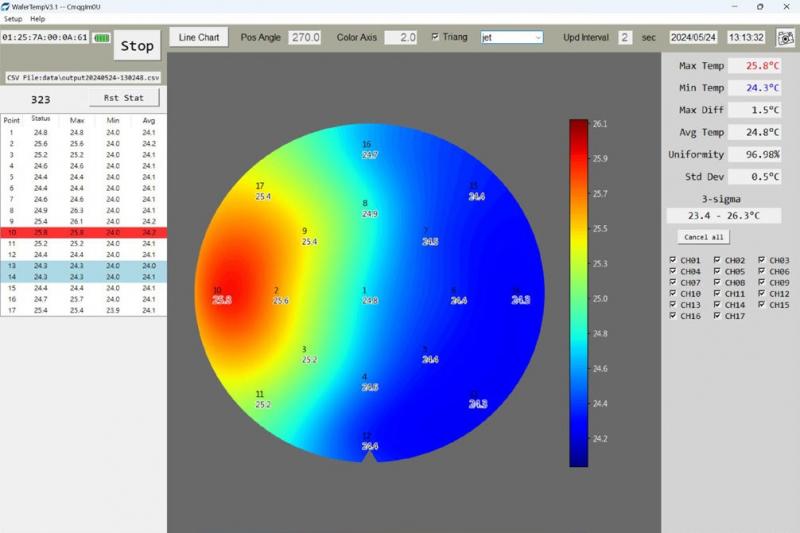

III. Tablet

THERMOWAY provide configured tablet computer with pre-set system parameters for users, and they can operate directly after booting.

Microsoft Surface Pro 9, preloaded with Windows 11

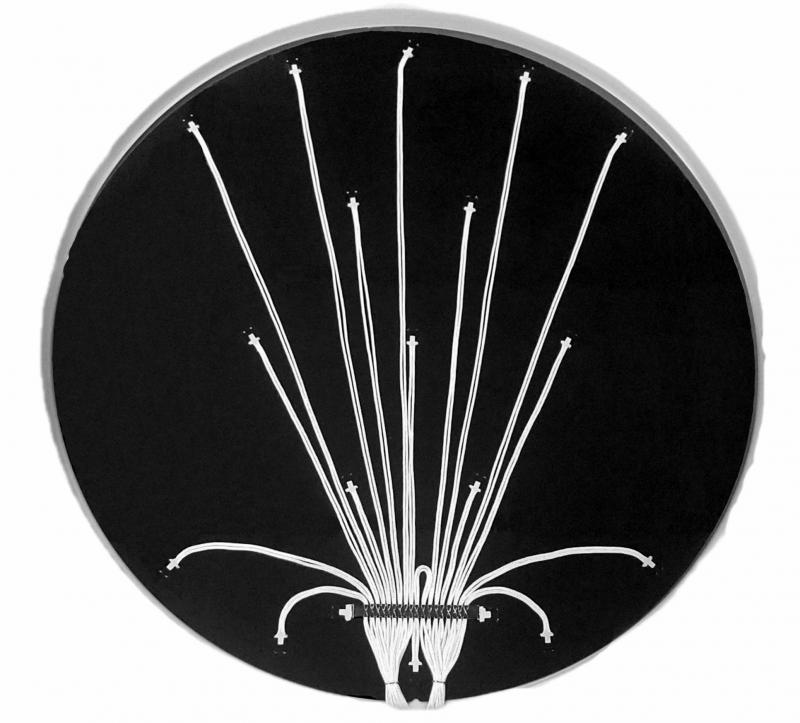

High Accuracy RTD Wafer

RTD WAFER is designed for processes requiring high precision temperature measurements such as semiconductor photoresist track systems, wafer probers, and many other types of semiconductor fabrication equipment.

RTD WAFER is designed for processes requiring high precision temperature measurements such as semiconductor photoresist track systems, wafer probers, and many other types of semiconductor fabrication equipment.

Through the sophisticated integrated design of THERMOWAY team, it brings high accuracy and stability.

|

✶ Application

- Measuring and recording wafer temperature of the process cycle: loading, heat-up, steady state, cool-down, and unloading.

- Improving wafer temperature control and uniformity, maintaining narrower process temperature windows.

- Managing production processes that have tight thermal performance specifications or providing inputs to SPC systems.

- Optimizing wafer processes during hardware or process development.

- Testing and benchmarking wafer fab equipment during final qualification, fab start-up, and requalification of repaired or upgraded systems.

|

|

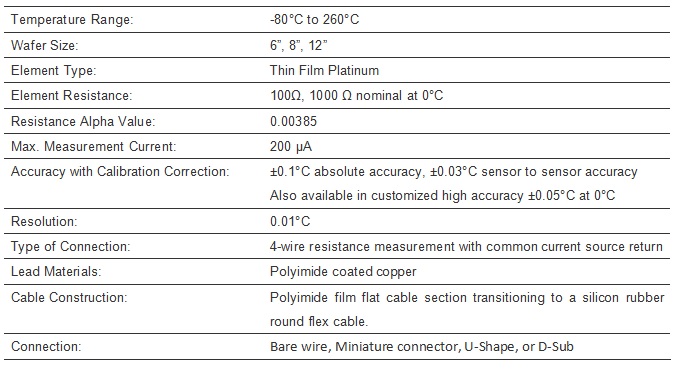

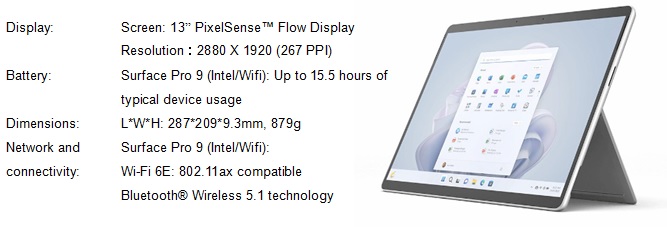

✶ Specification